Upgrade your sealing solutions with our high-performance EPE liner wads extrusion production line! EPE (Expanded Polyethylene) foam is an excellent material for sealing gaskets, offering superior cushioning, moisture resistance, and airtight protection.

✔ Cost-Effective – Cheaper than rubber or silicone, making it a budget-friendly alternative.

✔ Eco-Friendly & Recyclable – Reduces environmental impact while maintaining high performance.

✔ High Demand – Widely used in packaging, automotive, electronics, and construction industries.

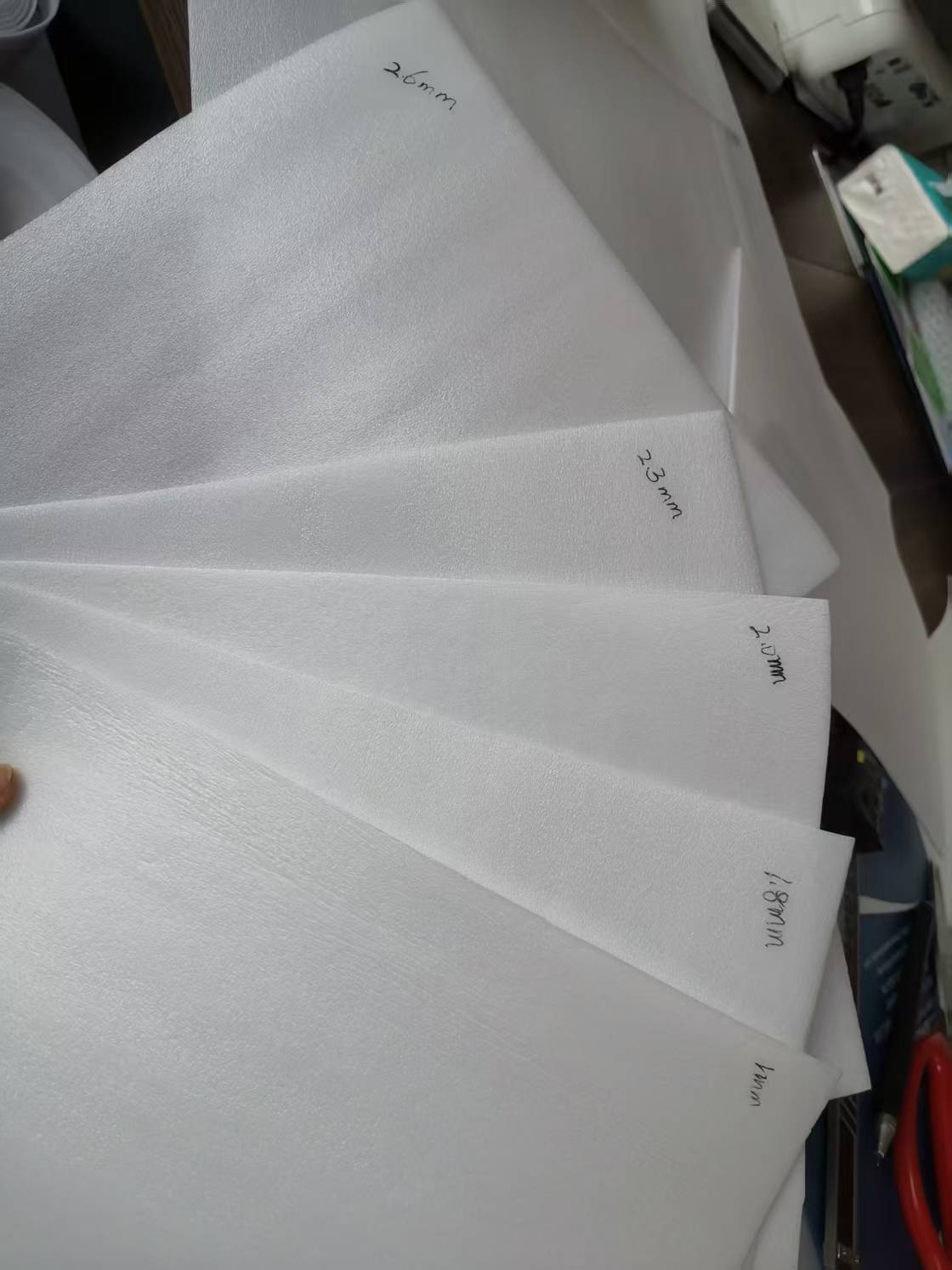

Our EPE foam extrusion line ensures precision cutting, uniform thickness, and high-speed production, delivering durable and lightweight sealing gaskets for various applications.

Automated extrusion for consistent quality

Customizable density & thickness to meet different sealing needs

Low energy consumption & minimal waste for sustainable manufacturing

Invest in a reliable EPE sealing gasket production solution that boosts efficiency and cuts costs! Contact us today for a quote and join the growing market of eco-friendly sealing products! MORE INFORMATION WhatsApp+8615288761312